REDUCE YOUR PACKING AND SHIPPING TIME

CUTTING EDGE PALLETIZING DESIGNS FOR THE FOOD AND BEVERAGE INDUSTRY

MOVE YOUR PRODUCTS QUICKLY AND EFFICIENTLY

Effective palletizing makes it easier to move bulk amounts of product from the producer to the destination. Whether it is a retail store, distribution center, or another production line, palletizing is important to the safety of the product. It provides protection from environmental hazards experienced during transportation and keeps the packages safe during storage.

Secondary packaging flows directly into palletizing even between rooms or across your plant. This is where our years of holistic automation design pay off for you. We can dramatically reduce the risk of damage or spoilage through automation. Our engineers find the most efficient route between secondary packaging and palletizing. We keep your products and employees safe while speeding them out the door.

You know exactly what product is being sent, and how much is on each pallet. Our robotic components have a smaller footprint to leave more space for inventory and movement. But smaller doesn’t mean less capable. Each arm can perform different tasks allowing for multiple products on the same pallet. You remove the risk of misplaced items while improving shipping safety through consistent binding or wrapping. Our pallet handling systems can even accommodate used and newer pallets in the same workflow.

How We Make Your Life Easier

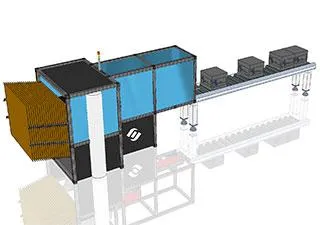

Case Erectors and Sealers

Kaitech erectors and sealers handle extra small to extra tall cases with a wide range of speed capabilities.

Case Erectors:

End slotted trays

Regular slotted cases

Stacking shoulders

display trays

Reinforced Corner Posts

Case Sealers:

Tape sealing

Hot melt adhesive

Cool adhesive

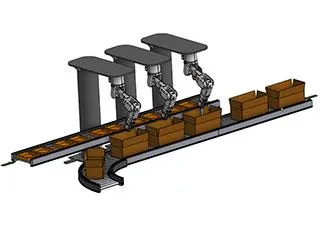

Case Packers

Kaitech case packers offer modular and flexible pick and place solutions. These provide the flexibility to update existing systems within limited spaces.

Packaging Types:

Trays

Bags

Boxes

Cans

Cartons

Gripping Tools:

Vacuum

Grippers

Clamping

Membranes

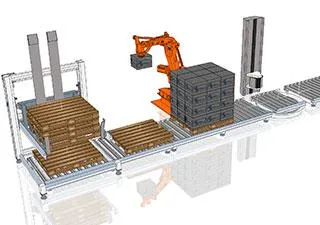

Palletizers & Wrappers

Custom engineered robotic palletizers and wrappers increase production with added speed and safety. Kaitech fits each palletizer and wrapper to accommodate new or used pallets and the wrapping material you require.

Small Footprint Cells

Partial and comprehensive automated solutions

Single- and Multi-line configurations

We Configure to Meet Your Needs

Robotic palletizers can pack and stack packaging of all shapes and sizes.

Boxes

Bags

Bundles

Cases

Trays

Cans

Cartons

Kaitech Understands that You Have Unique Needs

Robotic palletizing is becoming more popular across manufacturing disciplines around the world for many reasons. As time goes on, they are becoming more affordable to small and medium size companies. Robots have always been associated with dependability and reliability. Palletizing robots never call in sick, have a bad day, or need to take a break. They do it in the worst environments, from cold and wet to sterile, without disrupting valuable floorspace. And they do it perfectly. An often-overlooked feature to robotic palletizing is the impact on operator health. Many of the packages palletized weigh up to 50 pounds. This can pose a threat to worker health and safety. Taking the weight away from the operator means they stay healthier than if they had to manually move all that product themselves.

Palletizing automation extends beyond end-of-line consolidation. Effective packaging automation impacts your workforce and your production speed. We firmly believe the role of automation is to enhance and improve the process for both your business and your employees. Small footprint palletizing robots take on the arduous, repetitive tasks that can cause high turnover. This allows your labor budget to go toward harder to find subject matter experts that you may not have been able to afford before automating your palletizing operations among others.

Your environment and product mix is unique to your business. Kaitech engineers will spend the time to research and evaluate a range of solutions. We design each automated palletizing solution to accelerate production while elevating quality and safety. Whether you need a flexible, turnkey solution, a fully customized floor plan and existing component integration, or a combination of both, our engineers and automation experts work with you to design the right solution.

From palletizers that complete one task repeatedly to a more complex system that performs several functions as part of its design, Kaitech Automation helps companies like yours get the most out of your integration automation budget.